New initiative is exploring EV battery recycling tech

A new initiative is exploring the effectiveness of engineered bacteria for recovering critical metals from EV batteries in a push towards establishing a UK-based supply chain for these valuable elements.

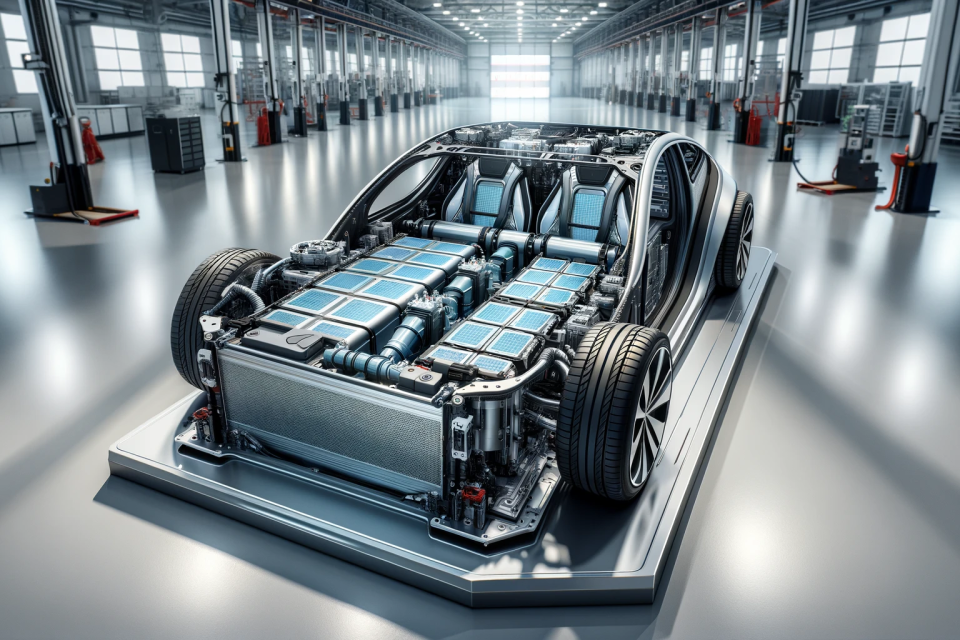

Engineered bacteria could be the solution for recovering critical metals from electric vehicle (EV) batteries at the end of their useful life, in a novel bio-based recycling process originating from the University of Edinburgh.

Experts in sustainable biotechnology at the university, under the leadership of Professor Louise Horsfall, are investigating this concept, where bacteria are employed to extract metallic compounds from lithium-ion batteries. Once retrieved and processed, these valuable elements, including cobalt, manganese, nickel, and lithium, could contribute to a new UK-based supply chain for rechargeable vehicle batteries.

The industrial biotechnology innovation centre (IBioIC) is backing the project to achieve industrial capacity, utilizing facilities at its FlexBio centre to refine the process in a larger bioreactor. Meanwhile, bacteria have been carefully chosen and modified using the Edinburgh Genome Foundry, which is based at the University of Edinburgh, to ensure their effectiveness on a large scale.

By employing a fermenter, bacteria are introduced to battery leachate—the liquid that remains after the initial processing stages—to stimulate a natural biological reaction.

Throughout the process, the bacteria generate nano-sized particles of the metallic compounds, resulting in sediment that can be separated and filtered from the residual liquid. The ongoing tests are conducted using material recovered from an EV battery previously utilized in a Nissan Leaf.

This latest research is part of the broader Reuse and Recycling of Lithium-Ion Batteries (ReLiB) initiative, spearheaded by the University of Birmingham and financially supported by the Faraday Institution—the UK’s independent institute for electrochemical energy storage science, skills development, market analysis, and early-stage commercialization.

As reported by the European Automobile Manufacturers’ Association (ACEA), battery electric vehicles represented 16.1% of total new car sales between January and June 2023, positioning the UK among the top ten European countries for EV sales.

As the market expands, so does the demand for initiatives that can alleviate the growing supply chain pressures and manage end-of-life battery disposal.

Consequently, as the reserves and resources of metals utilized in batteries dwindle, increasing amounts of raw minerals will be found within existing batteries themselves.

Currently, the majority of metals used in EV batteries are imported, including cobalt, manganese, nickel, and lithium.

Typically, these metals are extracted from African countries, where resource demand has triggered widespread conflicts and hardship. Developing alternative recycling methods could establish a more sustainable UK-based source of materials, reducing the strain on the global precious metals trade.

Professor Louise Horsfall, chair of sustainable biotechnology at the University of Edinburgh, said: “We often read about initiatives to reduce EV battery costs and improve their performance, but as the market for green transport grows, we also need to consider what happens to the technology once it is no longer fit for use. This project is about using cutting-edge sustainable biotechnology to find ways of tackling that challenge and, in turn, extract some of the most valuable metals that can go back into the sector at the early stages of vehicle production.”